830E Exhaust Reliability

THE PROBLEM: COMPROMISED EXHAUST DURABILITY

An Aletek client in Central Queensland wasn’t getting the product lifecycle they expected from their 830E exhaust systems. Component failure, unplanned downtime and additional financial costs were pain points that disrupted haul truck efficiency. This client needed an exhaust system that could satisfy the demands of operational conditions.

LOCATION

QUEENSLAND,

AUSTRALIA

CLIENT

CENTRAL QUEENSLAND MINE SITE

ASSET

KOMATSU 830E HAUL TRUCKS

PROJECT

FULL ALETEK EXHAUST KIT (REPLACEMENT)

0 hrs

EXHAUST UPGRADE

- 20 October 2016 – Full exhaust system fitted to client’s 830E

- 0 hours for Aletek kit

~15,000 hrs

SERVICE INTERVALS

- Bellows & fatigue parts changed as required

- Alignment with major service interval

~24,000 hrs

ENGINE REBUILD

- Mid to late 2020 – Engine rebuild typically 20,000 – 24,000 hrs

- Est. 20,000+ hrs, (assume 500 hrs/mth), estimate rebuild at 4 yrs

27,000+ hrs

4.5 YEARS IN SERVICE

- 12 May 2021 – Direct-fit system still in operation

- Achieved: Est. 27,000+ hrs, (assume 500 hrs/mth), 4.5 yrs

Extending Durability for 830E Exhausts

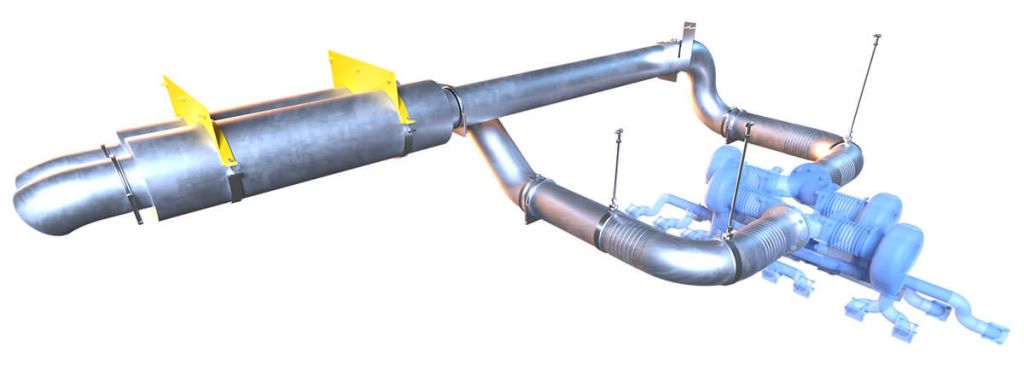

THE SOLUTION: ALETEK DIRECT-FIT REPLACEMENT EXHAUST FOR 830E

Aletek’s direct-fit exhaust for Komatsu 830E offers improvements to known OEM fatigue zones for durability and extended product lifecycle. This gives peace of mind and prevents unplanned downtime and maintenance costs. Aletek exhaust parts are compatible with OEM systems.

Aletek Exhaust Strategic Advantages

Proven Durability

4.5+ years lifecycle demonstrated on parts of our 830E exhaust kit.

Ease Of Fitment

Technical support, user guides and training available.

Direct-Fit System

Aletek exhaust components are compatible with OEM parts.

Exhaust Upgrade

Invest in an Aletek exhaust for cost savings and uptime.

“Apart from surface rust, the Aletek engine pipes are in great condition. This is almost too good to be true!”

ARNIE HILL

NATIONAL SALES & MARKETING MANAGER

Aletek Upgrades for 830E Haul Trucks

DIRECT-FIT EXHAUST SYSTEM & PARTS

- Solid machined flanges prevent cracking on engine pipe ends

- Compatible with Cummins engine specs

- Exhaust pipes and components interchangeable with OEM parts

- In-stock components include clamps, V-bands, tube pipe, etc

- Australian designed and manufactured

DUAL-WALL EXHAUST SYSTEM

- Impervious to fuels and oils

- Reduce surface temperatures below fuel flashpoints

- Flanges, clamps and mounts designed for minimal heat transfer

- Compatible with Cummins specs

- Exhaust pipes require dual-wall specific brackets and clamps

BLANKETS ADD-ON FOR EXHAUST SYSTEM

- Essential for fire mitigation

- Worker safety and protection of your investment in people

- Less engine fires, site shutdowns and insurance premiums

- Quick-fit springs are pre-fitted for faster installs and perfect tension

- Lobster-back design for superior fitment on pipe bend sections

YOUR NEXT STEPS

Are your 830E exhaust systems up to the operational demands required by your fleet? Is it worth gambling with unplanned downtime, extra maintenance costs and the risk of component failure? We challenge you to consider an 830E exhaust upgrade.

Purchasing an Aletek direct-fit exhaust system is a strategic investment to safeguard your 830E assets and reduce the chances of unplanned downtime. For additional fleet protection consider adding thermal blankets for reduced fire risk and worker safety.

Phone: Call us to speak with a specialist

Email: Contact us to talk more

Request a quote

"*" indicates required fields