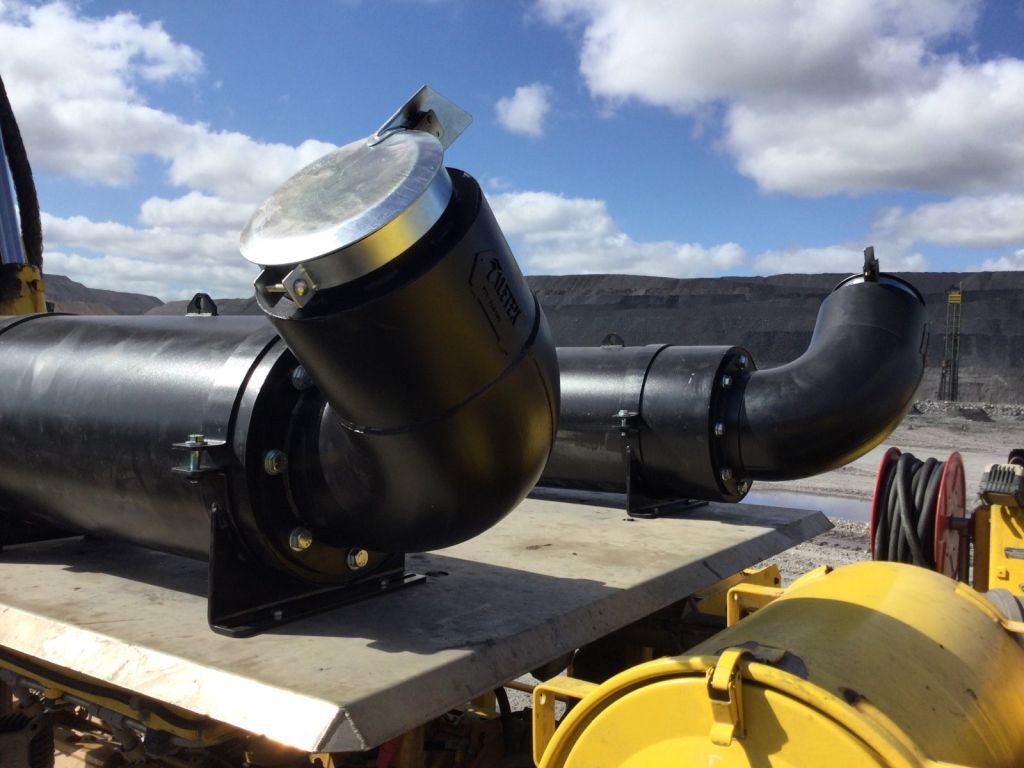

With Aletek dual-wall packages for Caterpillar, we can extend exhaust lifecycles. We offer exhausts for dump trucks, excavators and dozers.

Dual-Wall Exhaust Upgrades For Mining

Dual wall exhaust systems for mining equipment offer extended durability and can reduce fire risks. Dual skin exhaust pipes have a central layer of insulation to reduce external surface temperatures.

Installation assistance

Expert technical support

Testing and reports

Exhaust-related fleet audits

Durability and guaranteed protection

-

Integrated insulation reduces fire risk

-

Permanent protective solution

-

Increase productivity and cut downtime

-

Save on Total Cost of Ownership

-

A benchmark in dual-wall exhaust technology

-

Unmatched durability and strength

Installing dual-wall exhausts on mining assets can reduce engine fire risks, increase longevity, and streamline maintenance. Prior to considering a double wall exhaust upgrade, consider factors such as additional weight, mounting bracket replacement, and upfront costs.

What is a dual-wall Exhaust?

Mine sites typically implement dual-wall exhaust systems to solve specific problems. A few of these problems include minimising fire potential, improving endurance, and reducing maintenance.

- A dual-wall exhaust consists of an inner and outer pipe layer

- A central layer of silica between the two walls provides insulation for MDG 15 compliance (150°C surface temperature)

- Dual-wall exhaust pipes resist fuel and oil infiltration

- The systems connect directly to OEM turbo outlets

- When possible, dual-wall exhausts should follow OEM paths

- Installation requires upgraded hardware and custom brackets

Why consider a dual-wall exhaust upgrade?

Dual-wall exhaust systems for mining equipment are not only resistant to fuel and oil intrusion, but they also feature numerous design improvements. The central insulation of dual-wall setups reduces the external temperature of pipes. As a result, no thermal blankets are required on engine pipes, eliminating the risk of incorrect blanket installation.

To comply with the MDG 15 guideline, keeping the outer pipe temperature below the fuel flashpoint is critical. Dual-wall insulated exhaust pipes can achieve this objective and reduce temperatures below 150°C.

Aletek’s dual-wall exhaust systems can provide you with the following strategic benefits:

- Fire strategy: a purpose-engineered approach to fire mitigation

- Endurance: enhanced OEM designs reduces premature failure and unplanned downtime

- Integrated insulation: insulated pipes last longer (no blanket replacement on engine pipes)

- Simplified maintenance: no engine pipe blankets means no inspection, maintenance or removal during machine servicing

Ideal for assets like drill rigs, ultra class and sound

Aletek dual-wall exhausts can be an appealing upgrade for specific applications and mining assets. You can shield crew members from extreme exhaust burns by upgrading drill rigs to a dual-wall system. Adding dual-wall exhausts to large excavators and ultra-class assets can give them added durability. Sound suppression applications use dual-wall pipes for both acoustic and thermal reductions.

Aletek Dual-Wall exhausts are engineered to perfection

Aletek dual-wall exhausts offer extreme durability and integrated insulation that helps reduce your Total Cost of Ownership. For extended reliability, we design our exhausts with the following improvements:

- Reinforced components such as solid machined flanges

- Flanges, clamps and mounts designed for minimal heat transfer

- Strategically located vent ports help prevent inner wall failure

- Flexible elements absorb stresses caused by inner and outer wall heat differential

- Silica insulation reduces temperature better than dual-walls with air gaps (no insulation between walls)

- Insulation made from silica lasts longer than fibreglass

Dual-wall upgrades like no other

How does this all add up? A dual-wall Aletek system combines expert knowledge and experience. Dual-wall exhaust pipes no longer require thermal blankets. Our dual-wall exhaust upgrades not only reduce ownership costs but also extend the life of your equipment investment.

References: MDG 15 guideline and AS 5062:2016 Standard

We specialise in fabricating superior exhaust systems for mine fleets. Our focus is on mastering these niche products and providing reliable solutions based on robust design methodologies.

DOWNLOAD TECHNICAL INSIGHTS

Our Commitment

As engineers and fabricators, we take our jobs seriously. Design team members are acoustics, research and development, and 3D design experts. Matching OEM exhaust paths is ensured by the use of pipe jigs.

OUR EXHAUSTIVE COMMITMENT TO QUALITY

We are unrelenting in our commitment to quality. Every step of the process is carefully planned, from selecting the best raw materials to precision welding and powder coating.

A RIGOROUS DESIGN PROCESS

We examine OEM pipes in-depth to identify fatigue points or known issues. In addition, Aletek considers client feedback. Our prototyping process ensures that products meet OEM specifications with compatible flange profiles and clamps.

PIPE JIGS ENSURE CONSISTENCY

Aletek exhaust pipes match OEM exhaust paths. We construct a jig with the help of 3D scanning to match OEM pipes. These jigs are used for crafting pipes and for quality control. A specialist completes each part of the build process, which ensures quality.

THE ICING ON THE PIPE

Our fabrication team members are experts at creating the perfect exhaust. We use laser cutting and machined flanges to ensure the highest precision level. In the final stage, we apply a high-temperature powder coat in our signature gunmetal grey colour.

Subscribe

Is there a project you need help with?

Maybe you want to upgrade your fleet to reduce downtime. We’ve got dedicated Business Development Managers to help you meet your onsite goals. Get in touch to learn more and ask about our site-specific parts catalogues.

"*" indicates required fields