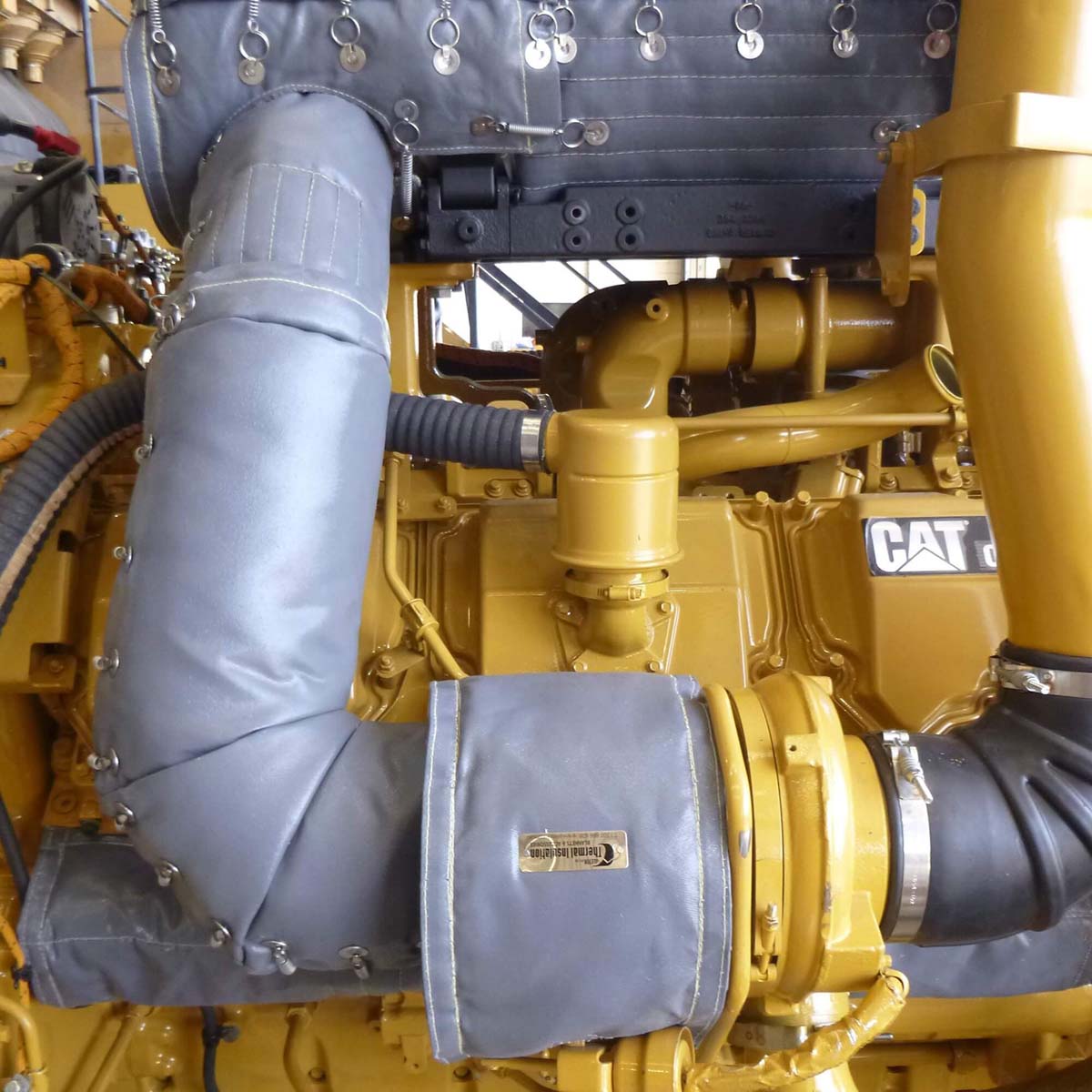

We tailor blanket packages to suit Caterpillar 3608 A4

Oil & Gas Thermal Lagging Kits

Are your assets protected? Our innovative four-layer thermal blankets help prevent engine fires. You can order exhaust lagging as a complete kit for new assets or as parts groups for engine rebuilds.

Support and resources for lagging installation

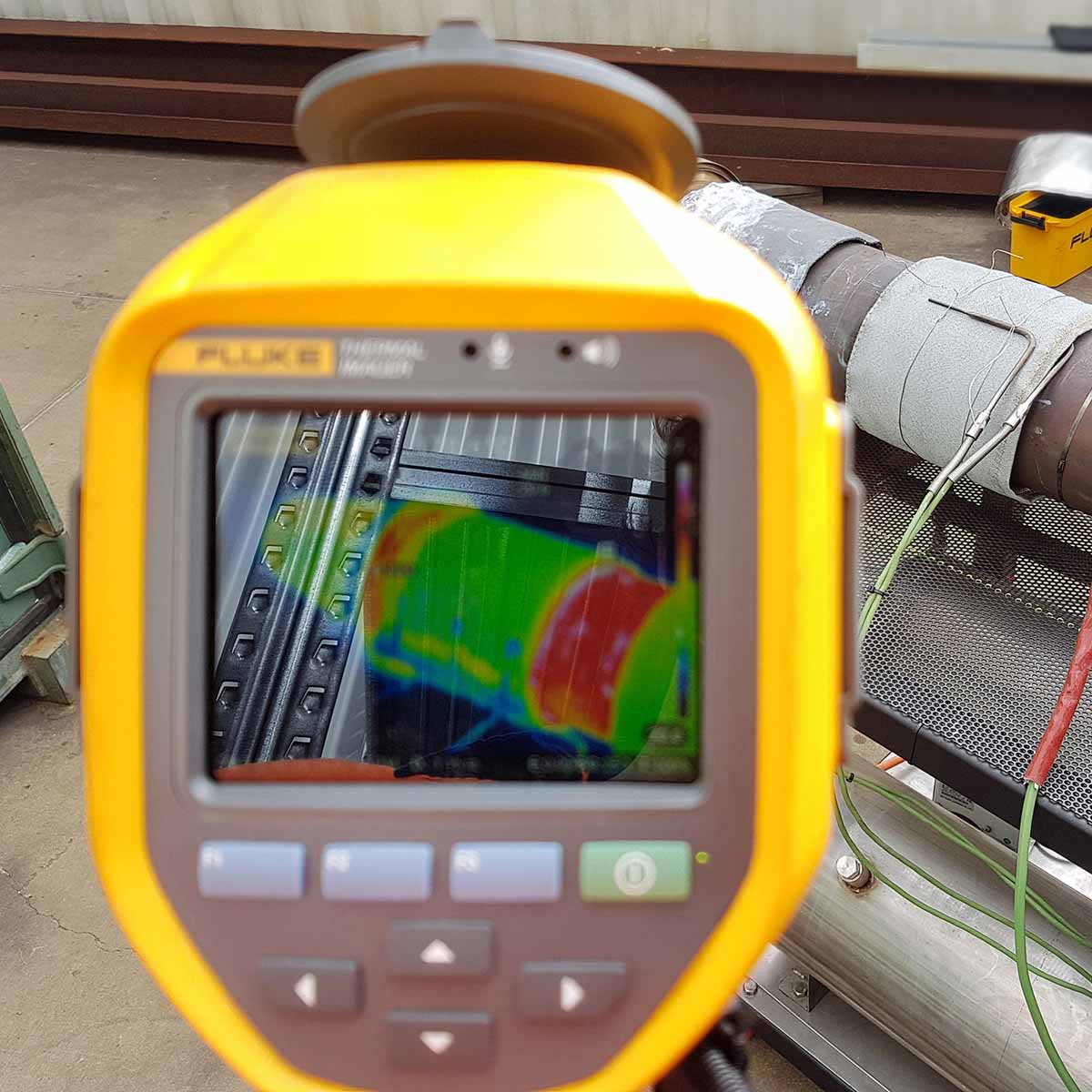

Thermal imaging and assessment

On-site asset audits for exhausts and lagging

Training for maintenance crews

Thermal blankets safeguard your assets

-

Comply with safety standards and mitigate fires

-

CR6 Safe - Oil & Gas Compression

-

Keep surface temperatures below fuel ignition points

-

Protect maintenance crews from extreme burns

-

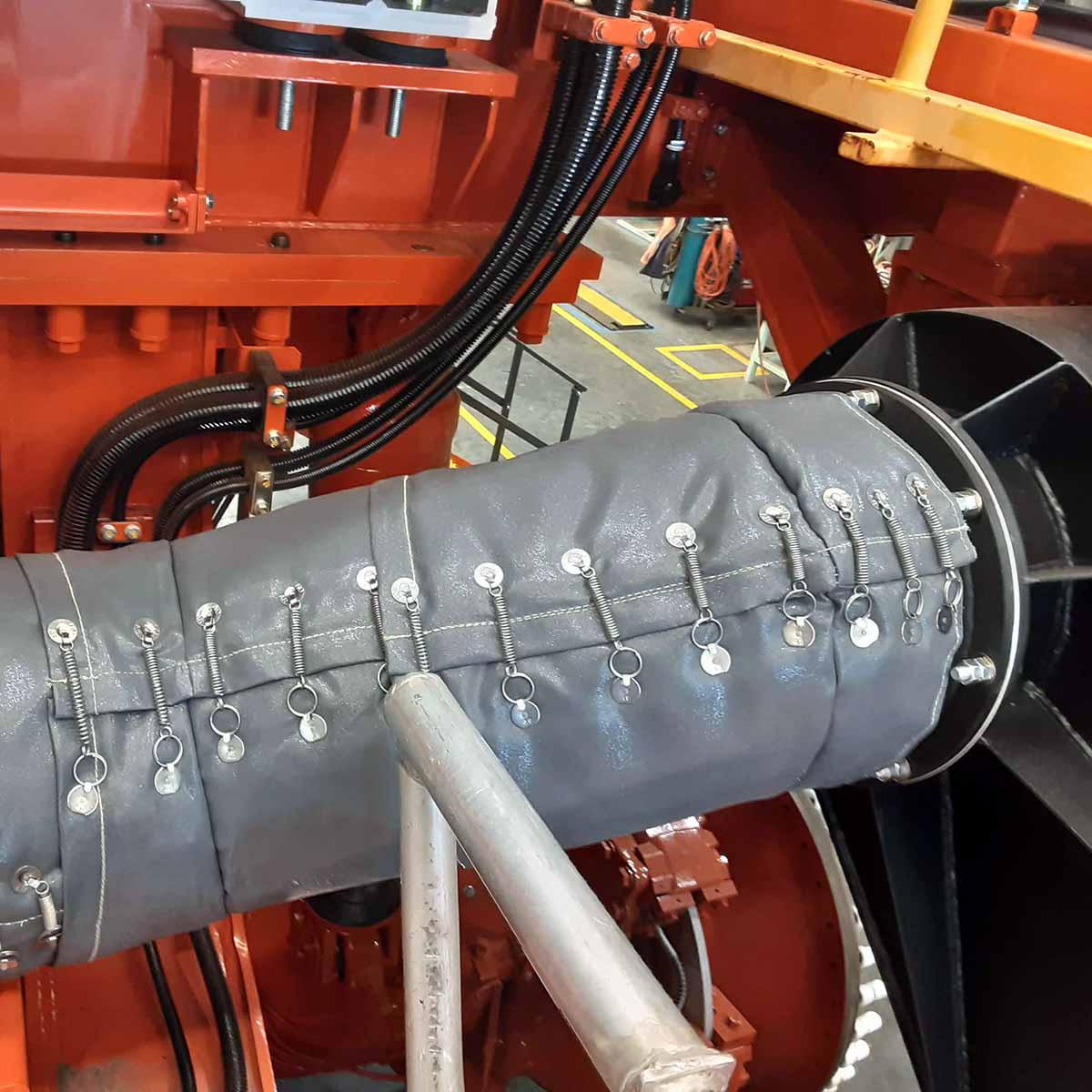

Our Oil & Gas compression engine exhaust lagging is easy to install and remove

-

Fits your equipment like a glove

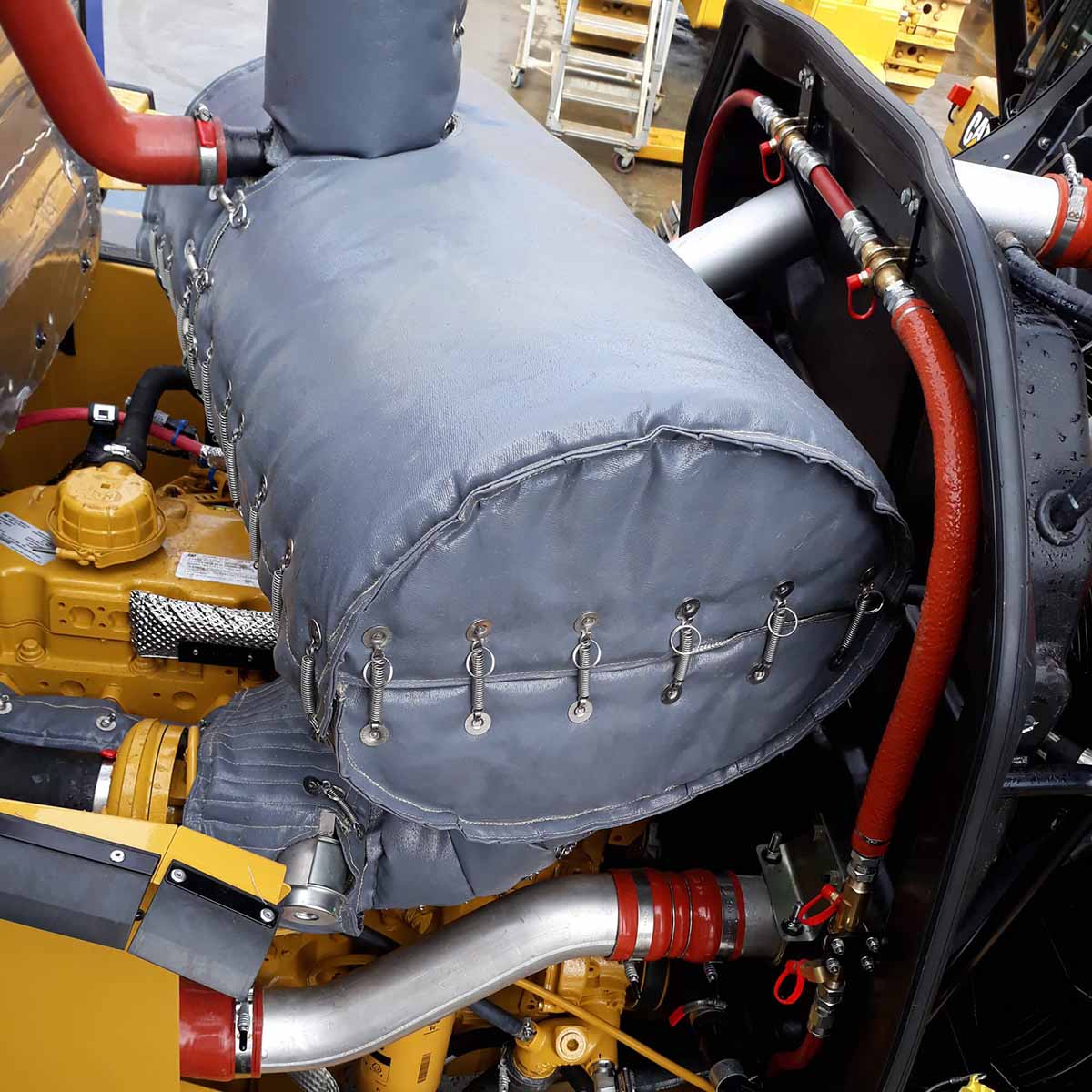

Shielding extreme-heated engine and exhaust parts with thermal insulation blankets is highly recommended. Using thermal blankets creates a controlled barrier between fire hazards and superheated parts. Our asset-specific exhaust lagging kits can help safeguard your gas compression engines.

Exhaust blankets can help prevent engine fires

Thermal insulation blankets create a physical barrier between superheated engine parts and flammable hazards. To prevent engine fires, cover these components with thermal blankets. You can think of blankets as your PPE (Personal Protective Equipment).

What makes our thermal blankets better?

CR6 safe

CR6 is a carcinogenic substance (cancer-causing) that is produced by some thermal blankets. Aletek Oil & Gas thermal blankets have been independently tested and proven to not produce harmful levels of CR6 due to our specialized thermal blanket materials.

Tailor Fit & Easy to Install

We tailor our blanket designs to suit each machine and fit snugly like a glove. Aletek blanket installation and removal is easy thanks to anchor hooks and minimal tie wires, making them popular with maintenance crews. Ditch the itch! Compared to competitors’ e-glass products, Aletek’s exhaust lagging has minimal itch.

Superheated engine components exposed

Manifold blankets

Under full load, engine manifolds can typically reach temperatures of 800°F (450°C). These temperatures exceed oil and fluid ignition temperatures. Our blankets reduce hot spots and prevent flammable liquids from infiltrating.

Turbo blankets

Turbos operate at extreme temperatures. Fuel leaks or ruptured hoses pose a high fire risk. Aletek turbo covers provide optimal shielding and facilitate access to fuel lines and inspection ports.

Engine pipe blankets for proximity risks

Use engine pipe blankets at locations that exceed fuel flashpoints. Typical zones include pipes in and around engine bays, junctions, and immediate hazards like grease pumps. Likewise, shielding pipes near high-voltage cables protects them from superheated exhausts.

Hexavalent Chromium (CR6) is a Class 1 carcinogen that poses a significant risk to maintenance crews and workers. CR6 is produced by some brands of thermal blankets when exposed to high heat, resulting in a powder-like substance that can accumulate on exhausts. During maintenance work, crews can be exposed to CR6, necessitating substantial personal protective equipment (PPE) and extensive decontamination with expensive chemicals.

Unlike many others in the industry, Aletek Oil & Gas Thermal Blankets are manufactured using material that do not produce unsafe levels of CR6, ensuring a safer working environment for maintenance crews. Additionally, by eliminating dangerous levels of CR6, Aletek’s thermal blankets downtime and maintenance efforts.

Built To Protect

DOWNLOAD TECHNICAL INSIGHTS

Our Commitment

Our blanket dedication to excellence

Aletek is unwavering in its pursuit of excellence. Our blanket production processes are meticulously planned, from sourcing premium materials to expert sewing and assembly.

Product designs underpinned by R&D

Our latest thermal blankets incorporate lessons learned from testing. For instance, using a thinner coating can reduce burn potential. Thermal imaging has helped identify heat issues and improve designs between section overlaps.

CNC pattern production for consistency

Our blanket pattern cutting is automated with a CNC flatbed cutter. We believe it is the only one in the Southern Hemisphere. Our team of experienced sewers and finishers completes the production of thermal blankets.

A final wrap-up on blankets

From 3D scanning to CAD, our product design phase is well-defined. Controlled templates, lean workflows and quality checks inform our manufacturing process. An expert oversees design and templates to ensure continued excellence in our Thermal Division.

THERMAL BLANKETS

Subscribe

Is there a project you need help with?

Maybe you want to upgrade your fleet to reduce downtime. We’ve got dedicated Business Development Managers to help you meet your onsite goals. Get in touch to learn more and ask about our site-specific parts catalogues.

"*" indicates required fields